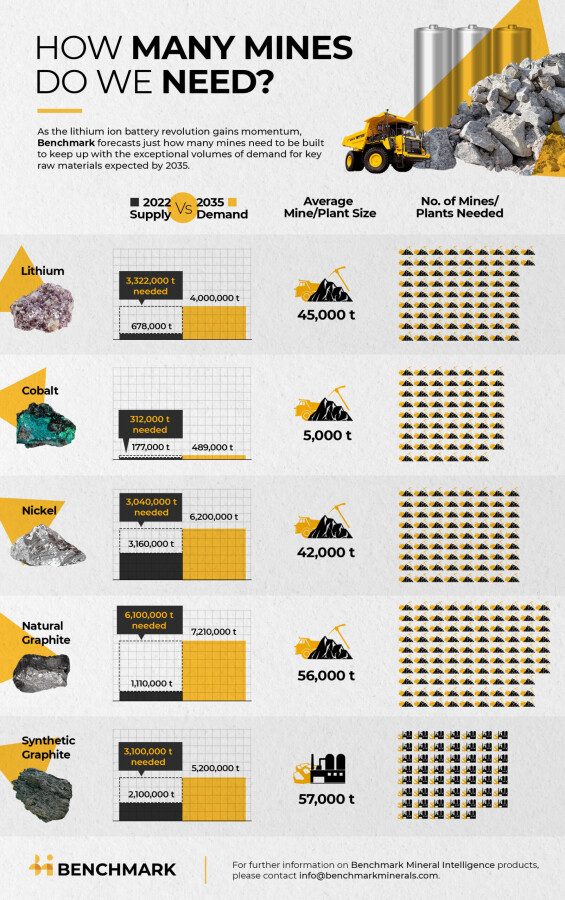

300 Mines or More Required By 2035 To Meet World Battery Demand For EV and Infrastructure

Home > Blog > Blog Details

Cobalt Mines

Benchmark further breaks down the demand by raw material type whereby 97 natural flake graphite mines would need to be constructed producing an average 56,000 tonnes with no recycling contribution for production of anode materials. It goes on to highlight that at the moment all recycling effort is just focused on recovering the battery cathode materials rather than the anode. Efforts must be done on anode recovery to reduce its dependency on fresh mined material. Countries focused on graphite would be Africa and China.

(Image Source: benchmarkminerals.com)

Benchmarkmineral.com (Benchmark) recently reported that in the coming decade more than 300 new mines would have to be constructed in order to meet the rising demand for EV and energy storage batteries.

To be specific, 384 mines producing raw materials such as graphite, lithium, nickel and cobalt are required to meet demand by 2035. If we take into account efforts to recycle raw materials, the number would slightly reduce to 336 mines.

Chargesini EV Charging Facility

With the increase in demand especially post 2030, recycling will play a very crucial role to meet the expected six-fold raise in demand for lithium ion. With the constant evolution of technology, efforts in recycling could reduce the need for new mines over time.

There would be about 74 new mines required to mine Lithium with an average output of 45,000 tonnes. This number reduces to 59, if recycling efforts are taken into consideration. Main lithium producer for the world market is Australia.

As for nickel, Benchmark estimates a need of 72 new mines producing 42,500 tonnes while construction of 62 new mines to produce 5,000 tonnes of cobalt. If recycling efforts are ramped up, this number can be greatly reduced to just 38 mines.